Obliteration and Restoration of Serial Numbers

What is a Firearm Serial Number?

Every firearm has a unique serial number or code permanently marked by the manufacturer to identify each weapon. It is typically stamped or engraved on the frame or receiver of the firearm. Serial numbers allow law enforcement agencies to trace the origin, ownership history, identify stolen firearms, and potential involvement of a firearm in criminal activities.

Figure: Close-Up View of Firearm Serial Number

Tampering with Firearm Serial Numbers

It is required by law in most countries for all firearms to have a visible and legible serial number, and tampering with or removing it is considered a serious criminal offence. However, criminals often attempt to erase these serial numbers by filing, grinding, drilling, or using corrosive chemicals like acid. They do this to prevent the firearm from being traced back to its origin or linked to illegal activities, such as thefts, trafficking, or violent crimes. By obliterating the serial number, they attempt to erase any connection between the weapon and its previous owner, the manufacturer, or any crime it may have been used in. This deliberate act of concealment interferes with criminal investigations, which is why restoring obliterated serial numbers has become an important part of forensic firearm analysis.

Figure: Obliterated Serial Number on a Firearm

Common Methods of Serial Number Obliteration

Criminals use various methods to deliberately erase or hide the original serial number stamped on a firearm. These methods fall under mechanical, thermal, and chemical techniques. Each method has a different impact on the metal surface and subsurface, which influences whether the number can be restored.

Grinding or Filing

A mechanical tool, such as a grinder, metal file, or abrasive wheel, is used to physically remove the surface of the metal where the serial number is stamped. Even though the surface is removed, the deformed metal beneath the stamping may still retain trace impressions that can be restored using chemical etching or magnetic particle inspection (MPI).

Peening or Hammering

The surface is repeatedly struck with a hammer, punch, or other blunt tool to distort the metal. The impact flattens the stamped digits, creating a cratered or pitted appearance. The restorability is determined by the depth of deformation.

Overstamping

A new set of digits or letters is stamped over the original serial number to obscure or confuse the identification. This results in double-layered deformations as both the original and the fake number deform the metal differently. With careful restoration, both number layers can sometimes be distinguished.

Chemical Corrosion

Strong acids or corrosive agents (such as nitric acid, hydrochloric acid) are applied to dissolve the metal surface where the serial number is located. Restoration is difficult if the etching is deep, but superficial corrosion may still allow for recovery.

Cutting, Drilling, or Milling

The area containing the serial number is completely cut out, drilled through, or machined off using power tools or lathes. This is the most aggressive form of obliteration and is often irreversible.

Burning or Melting

The surface is exposed to high heat (such as a blowtorch or welding flame) in an attempt to melt or deform the metal. Thermal damage may alter the crystalline structure of the metal, making chemical restoration ineffective.

Methods of Restoration of Serial Numbers in Firearms

Restoration of Serial Numbers in Firearms refers to the forensic process of recovering obliterated or damaged serial numbers from firearms. Serial numbers are usually stamped on the surface of weapons using force, which deforms the metal layers beneath the visible surface (called plastic deformation). Even if the top layer is scratched or altered, the metal beneath retains traces of the original number.

Forensic scientists can often restore these numbers using specialised techniques discussed below:

1. Chemical Etching

Chemical etching is the most commonly used method for restoring obliterated serial numbers in firearms. It relies on the principle that when a number is stamped into metal, the impact causes deformation of the metal layers beneath the visible surface. Even if the top layer is removed by grinding, filing, or polishing, the subsurface deformation remains. Chemical etching reveals this hidden deformation by reacting differently with the strained (deformed) and unstrained (normal) metal.

✏️ Principle:

When a strong acid or chemical reagent is applied to the polished surface of the metal, it etches the metal at different rates. Strained areas beneath the stamped digits corrode faster, whereas the unstrained areas corrode more slowly. This creates a contrast that makes the original numbers visible, either to the naked eye or under a microscope.

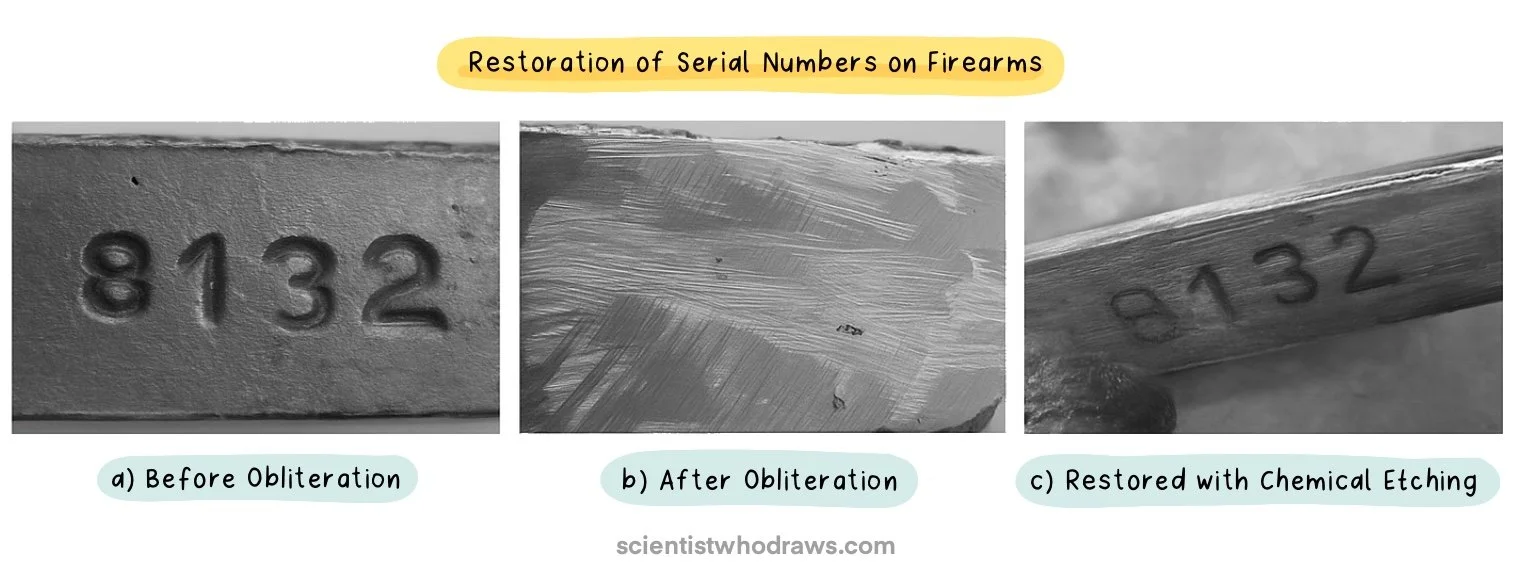

Figure: Restoration of Firearm Serial Number using Chemical Etching

✏️ Procedure:

Surface Preparation: Before any restoration begins, the surface must be degreased and stripped of any paint coatings. The obliterated area is then polished using fine sandpaper or an abrasive to obtain a smooth and clean surface for even etching. This also removes any oxidation or residue on the surface to minimise false positive reactions.

Selection of Etching Reagent: The choice of chemical depends on the metal of the firearm:

Steel: Fry's Reagent (CuCl₂ + HCl + H₂O)

Aluminium: 10% NaOH (Sodium Hydroxide)

Cast iron: Nitric acid solution

Zinc alloys: Acetic acid or other mild acids

Application of Reagent: The etching solution is applied with a cotton swab or dropped onto the surface. The reaction is monitored closely to prevent over-etching. The area is rinsed and dried, and the process may be repeated to enhance visibility.

Visualisation: Once the etched numbers appear, they are examined under oblique lighting or low-power magnification. The process is photographed and documented as forensic evidence.

2. Magnetic Particle Inspection

Magnetic Particle Inspection (MPI) is a non-destructive technique used to restore obliterated serial numbers in ferromagnetic materials such as steel and iron. Magnetic fields behave differently in deformed metal regions, allowing hidden or altered serial numbers to be visualised through the accumulation of magnetic particles.

✏️ Principle:

When a ferromagnetic object (like a firearm) is magnetised, the magnetic field lines flow uniformly through the metal. However, if the metal has been deformed, such as by stamping a serial number, those lines are disrupted at the areas of deformation.

If fine magnetic particles (usually iron filings or a magnetic powder suspended in liquid) are applied to the surface during magnetisation, they gather at these distorted magnetic field regions, effectively highlighting the original serial number even if it has been filed off.

✏️ Procedure:

Surface Preparation: The surface is cleaned and polished to remove any contaminants like oil, rust, or paint. A smooth surface enhances visibility and prevents particle clumping.

Magnetisation: A uniform magnetic field is established across the obliterated area using either direct magnetisation (electric current passed through the object) or indirect magnetisation (placing the object inside a magnetic field).

Application of Magnetic Particles: Dry powder, made from very fine iron particles, is used for smooth surfaces. Wet suspension, made by mixing magnetic particles in a liquid (usually oil or water), is used for curved or rough surfaces. The magnetic particles accumulate at the sites of original stamped digits where the magnetic field is distorted, making the hidden serial number visible.

Visualisation: The restored digits appear as dark lines or patterns where particles are concentrated. Observations can be enhanced with UV light if fluorescent magnetic particles are used. Photographic documentation is done immediately.

3. Heat Tinting

Heat tinting is used to restore obliterated serial numbers on firearms or other metallic surfaces by applying controlled heat to the surface.

✏️ Principle:

It relies on the principle that metal responds to heat differently in deformed and undeformed areas due to changes in internal structure caused by stamping. Upon heating, these deformed regions oxidise or change colour at a different rate than the surrounding metal. This creates a contrast between the original stamped areas and the rest of the surface, making the hidden serial number visible.

✏️ Procedure:

Surface Preparation: The obliterated area is polished using sandpaper or abrasives to remove corrosion, paint, or surface irregularities. A uniform surface ensures even heating.

Controlled Heating: A low-temperature heat source such as a Bunsen burner, heat gun, or hot plate is used. The metal is heated gradually and uniformly.

Oxidation: As the temperature rises, it causes the metal to form thin oxide layers, which reflect light to produce interference colours such as yellow, brown, purple, and blue. The deformed regions oxidise at different rates, and the digits begin to appear faintly. This colour change helps visually distinguish the original digit impressions from the rest of the surface.

Observation: The area is observed under angled light or a stereomicroscope. The best visibility occurs when the colour contrast is maximised between the deformed and undeformed zones. The restored number is photographed and documented.